Equipment and infrastructure support

-

01 Purpose

| Supports rental and utilization of expensive equipment that is difficult for a single company to purchase.

-

02 Support details

| Ultra-precision processing equipment, measurement/evaluation equipment, design software

-

03

Only those who have completed training can directly use equipment and infrastructure (24 hours open)

-

04

Support design, processing, measurement / evaluation

Optical design

Optical design for visible light and ultraviolet and infrared areas, spherical and non-corrosive surfaces, and free-form optical design

-

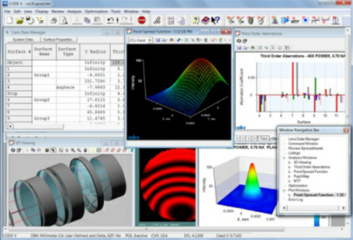

[CODE V OPTICAL DESIGN PROGRAM]

-

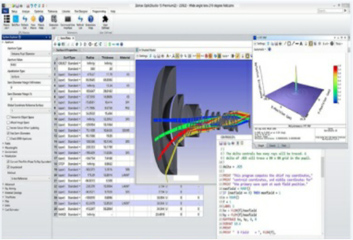

[ThinkPlate Design Program]

-

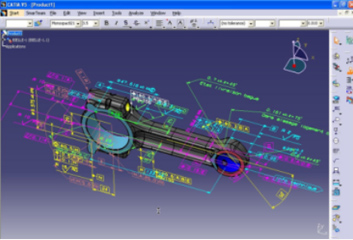

[CATIA Optical Design Program]

High accuracy machining

Non-placeable, ultra-precise grinding and cutting

-

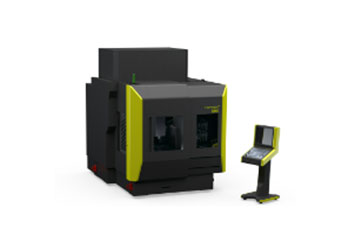

Ultra precision freeform diamond

turning machine / Nanoform Xtc -

Aspheric Ultra precision CNC

Multi axis Hybrid machine / 650FG v2 -

Ultra precision nano grooving

machine / NIC-300PS5-N5 -

High Precision

Vertical Machine / S90 -

Ultra Precision CNC

Tool Grinder / PG4 -

High Precision

5-axis Machine / M2 -

Ultra precision aspheric measuring instruments

/ PGI Freeform XL -

Noncontact ultra precision shape measuring

instruments / LuphoScan 420HD -

3D Optical surface profile /

NPFLEX -

3D measuring laser microscope /

OLS5000-LAF

Measurement and assessment

Performance Evaluation of Optical Fiber Optic System for Visual Light and Ultraviolet Radiation

-

MTF Measuring Instrument for Optical System

/ ImageMaster Universal -

Optical lens module Tester for infrared

/ Imagemaster HR MAX -

Ultra precision final inspection system for lens

/ LAS-UP -

UV Visible IR Transmittance Reflectance Tester

/ Lambda 1050+ -

IR transmittance tester at variable incident angle

/ Frontier -

Smart aligner Optical Sensor

/ ProCAM Align Smart -

Optical lens module performance Tester

/ NED-LMD E101

TOP